How America Was Built

HAWB 1954-1976: NACA, NASA, Richard Whitcomb, the Area Rule, Supercritical Wings, and Winglets

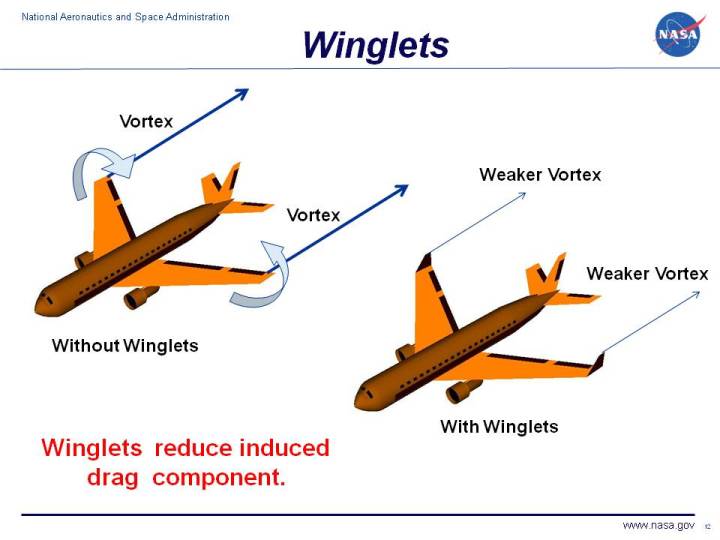

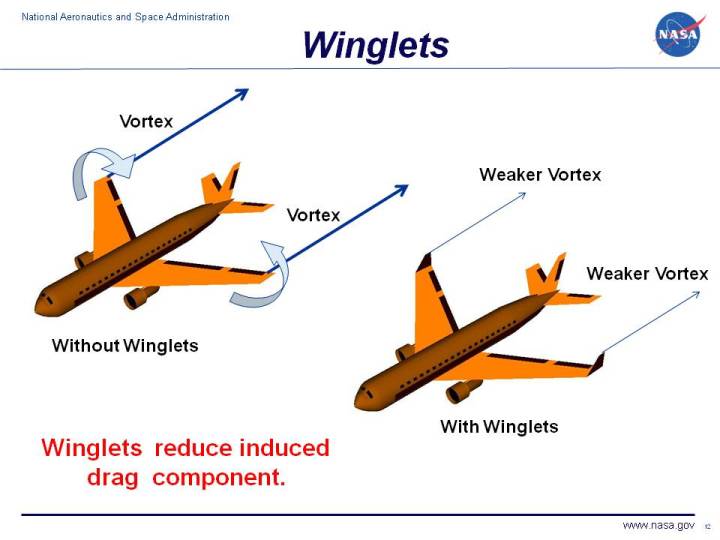

Do you like to look at aircraft? Have you ever wondered about the forward, second-deck hump of the Boeing 747? What about winglets, those vertical tips at the end of wings?

These are all the result of the U.S. government's active intervention into the economy. When Republicans, conservatives, and libertarians insist that nothing good comes from government, remember winglets and the 747's hump and realize that they are either lying shamelessly, or are embarrassingly ignorant, about the role of government.

By the end of the Second World War in mid-1945, aircraft design was on the verge of breaking the sound barrier. But aerodynamicists and aeronautical engineers were finding that achieving Mach speeds was much more difficult than anticipated. What we now know is that as an aircraft approaches Mach One in velocity, the aircraft's body generates shock waves in the air, which causes a huge spike in aerodynamic drag. The then accepted equations mathematically describing the aerodynamic behavior of aircraft just did not account for shockwaves formed at the speed of sound.

In 1943, the National Advisory Committee for Aeronautics (NACA, the forerunner of NASA) Langley Research Center in Hampton, Virginia hired a young aerodynamicist who had just graduated from the Worcester Polytechnic Institute in Massachusetts. His name was Richard T. Whitcomb, and he was originally assigned to the Flight Instrument Division. This was not an area that held any interest for Whitcomb. He wanted to work in aerodynamics, and made himself enough of a nuisance that he was soon assigned to Langley's Eight-Foot High-Speed Tunnel, under the supervision of John Stack.

Stack had just obtained approval to increase the power in the tunnel from 8,000 horsepower to 16,000 horsepower, so this was the first project Whitcomb worked on as a government employee. The upgraded wind tunnel was completed in the spring of 1945, and immediately researchers were able to obtain, for the first time, reliable airflow data for speeds up to Mach .95.

But Stack and his team wanted even higher velocity. Over the next five years, Langley's wind tunnel engineers struggled to find a way to boost airflow to true transonic. In the meantime, wing and fuselage designs could only be tested at Mach speeds by attaching them to rockets. But these tests provided very limited data. Most importantly, it was not possible to obtain the Schlieren photographs that captured the shock wave patterns of high-speed airflows. These photos could only be taken in wind tunnels. (In the 1970s, NASA researchers would discover how to use diffracted sunlight in the atmosphere to obtain Schlieren photographs of objects in free flight.)

Schlieren photograph of flow around airplane models showing the effect of sweptback wing design on shock waves (NASA history photograph).

Also, rocket tests were "100 times as expensive as a wind tunnel test," according to one engineer.

In 1950, Stack and his team of engineers, which included Whitcomb, developed a "slotted-throat" design for the 8-foot wind tunnel that allowed them to achieve transsonic airflows. For the first time, aerodynamic researchers had a tool to investigate precisely what airflows did at transonic speed, and what might be causing the puzzling massive increase in drag encountered at the speed of sound. This development of the slotted-throat transonic wind tunnel at the Langley Research Center was deemed so important to the advancement of aeronautics that Stack and his team at Langley were awarded the Collier Trophy in 1951. (Since 1910, the Collier Trophy has been awarded annually by the Aero Club of America, National Chapter (now the National Aeronautic Association), " 'for the greatest achievement in aeronautics or astronautics in America, with respect to improving the performance, efficiency, and safety of air or space vehicles, the value of which has been thoroughly demonstrated by actual use during the preceding year.' The list of Collier winners represents a timeline of aviation, as many of the awardees mark major events in the history of flight.")

Now the scientists and engineers at Langley could see the turbulence that develops around an aircraft structure as it approaches Mach, but they still had to explain and understand it before they could begin developing solutions. Aerodynamic theory at the time rested on Bernoulli's principle that an increase in the speed of a fluid occurs in conjunction with a decrease in pressure or a decrease in the fluid's potential energy. This handily explained why a wing generated enough lift to sustain flight at subsonic velocity. But the theory obviously did not apply at transonic velocity.

In late 1951 or early 1952, German aerodynamicist Dr. Adolf Busemann, presented a technical symposium on transonic airflows. Dr. Busemann had developed the concept of swept wings in Germany in the mid-1930s, and after World War Two had come to work at the Langley research center. It was Busemann's presentation that led Whitcomb to the breakthough in understanding and mastering transonic flows and shockwaves. Busemann explained that at the speed of sound, Bernoulli's theorem did not apply, and suggested thinking of the airflow as a series of stream tubes, the size of which remained constant. According to Lane E. Wallace's 1998 article, The Whitcomb Area Rule: NACA Aerodynamics Research and Innovation, in the official NASA history From Engineering Science To Big Science: The NACA and NASA Collier Trophy, edited by Pamela E. Mack,

In working with this kind of flow, therefore, the Langley engineers had to look at themselves as "pipefitters." Busemann's pipefitting metaphor caught the attention of Whitcomb, who was in the symposium audience. Soon after that Whitcomb was, quite literally, sitting with his feet up on his desk one day, contemplating the unusual shock waves he had encountered in the transonic wind tunnel. He thought of Busemann's analogy of pipes flowing over a wing-body shape and suddenly, as he described it later, a light went on.

The shock waves were larger than anticipated, he realized, because the stream tubes did not get narrower or change shape, meaning that any local increase in area or drag would affect the entire configuration in all directions, and for a greater distance. More importantly, that meant that in trying to reduce the drag, he could not look at the wing and fuselage as separate entities. He had to look at the entire cross-sectional area of the design and try to keep it as smooth a curve as possible as it increased and decreased around the fuselage, wing and tail. In an instant of clarity and inspiration, he had discovered the area rule.What Whitcomb had discovered -- the area rule -- was that formation of shock waves are minimized when the total area distribution of an aircraft is smooth. For an aircraft moving forward, when the wings enter the air stream there is a sudden increase in the aircraft area distribution, causing a sudden spike in shock waves generated. Whitcomb found that making the fuselage narrower in a "coke bottle shape" smoothed out the aircraft area distribution, eliminating most of the shock waves that were causing so much drag at transonic and supersonic speeds, particularly between Mach 0.75 and 1.2.

For commercial aircraft, it is much cheaper to design and build a fuselage with a constant cross section, so the "coke bottle shape" is never a good option. In the case of the 747, Boeing designers solved the problem by creating the 747's distinctive front hump, which contains a second level passenger deck. Speed was a major design factor since the 747 was designed for ultra-long distance flights. With a maximum speed of .855 to .860 Mach, the 747 remains the fastest jetliner in the world, despite its massive size, thanks to Boeing's unique application of Whitcomb's area rule.

Seeking approval to test his theory in the wind tunnels, Whitcomb tried to explain his insight. Stack and others were skeptical, but Busemann understood immediately what Whitcomb was trying to explain. Busemann told the others at the presentation that Whitcomb's idea was "brilliant" and Busemann's influence was great enough that Stack gave his approval for the tests.

In August 1952, not long after the wind tunnel experiments had proven Whitcomb's theory correct, a team of engineers from Convair were at Langley to test models of their new F-102 fighter aircraft in the High-Speed Tunnel. The Air Force contract with Convair specified that the F-102 be capable of supersonic flight. But the wind tunnel tests at Langley showed that Convair's design would not meet the supersonic specification. Wallace relates what next transpired:

1953 NASA photos show models of the delta-winged Convair F-102 before, (left) and after (right) modification to take advantage of Whitcomb's "area rule. These models are mounted on rockets for flight at the Wallops Island launch site. For scale, note the man in the lower right in the right picture. (NASA Photo).

The reluctance of Convair's management to discard the production tooling they had already installed in San Diego illuminates the wisdom of First Secretary of the Treasury Alexander Hamilton, who rejected the "free market" ideas of Adam Smith. In his chapter on Whitcomb, Wallace writes:

In August 1952, not long after the wind tunnel experiments had proven Whitcomb's theory correct, a team of engineers from Convair were at Langley to test models of their new F-102 fighter aircraft in the High-Speed Tunnel. The Air Force contract with Convair specified that the F-102 be capable of supersonic flight. But the wind tunnel tests at Langley showed that Convair's design would not meet the supersonic specification. Wallace relates what next transpired:

Shown the disappointing test results, the engineers asked the Langley engineers if they had any suggestions. Whitcomb's first research memorandum on the area rule would not be published for another month, but he had completed his tests on the various wing-body combinations using indented fuselage shapes. He explained his findings and the area rule concept to the Convair team.

Intrigued, the Convair engineers worked with Whitcomb over the next few months to experiment with modifying the F-102 design and building a model that incorporated the area rule concept. At the same time, however, the company continued work on the original F-102 prototype.

Even at that point, Convair might have continued to press for production of the design as it was, given that the tooling and production line in its San Diego plant was already set, except for one crucial factor. The Air Force officials working on the F-102 design were aware of Whitcomb's area rule and the fact that a modified F-102 model, based on that concept, had achieved supersonic speeds in wind tunnel tests. Consequently, the Air Force realized that the F-102 was not the best that Convair could do. Whitcomb's experiments had proven that a supersonic airplane was possible, and the Air Force decided to settle for no less. The F-102 program manager at Wright Field in Ohio informed Convair that if the company did not modify the F-102 to achieve supersonic flight, the contract for the fighter/interceptor would be cancelled.

1953 NASA photos show models of the delta-winged Convair F-102 before, (left) and after (right) modification to take advantage of Whitcomb's "area rule. These models are mounted on rockets for flight at the Wallops Island launch site. For scale, note the man in the lower right in the right picture. (NASA Photo).

The reluctance of Convair's management to discard the production tooling they had already installed in San Diego illuminates the wisdom of First Secretary of the Treasury Alexander Hamilton, who rejected the "free market" ideas of Adam Smith. In his chapter on Whitcomb, Wallace writes:

NACA or NASA engineers tend to measure the success of a new idea or technology strictly in terms of technical objectives met. Industry, on the other hand, measures innovative success in terms of profit dollars generated within a specified payback period. Consequently, a new approach or technology, even if it is technically "better," may be rejected by industry if its use involves extra costs for the manufacturer. These costs can be in retooling for a new design, replacing machinery, or even in retraining employees or changing the traditional ideas and approaches of its engineers. All of these factors can produce resistance to a new idea or technology within a company, and overcoming that resistance can be a difficult process.

Here is Hamilton, writing in 1791:

Experience teaches, that men are often so much governed by what they are accustomed to see and practise, that the simplest and most obvious improvements, in the most ordinary occupations, are adopted with hesitation, reluctance, and by slow gradations…. To produce the desirable changes as early as may be expedient may therefore require the incitement and patronage of government… it is of importance that the confidence of cautious, sagacious capitalists, both citizens and foreigners, should be excited. And to inspire this description of persons with confidence, it is essential that they should be made to see in any project which is new—and for that reason alone, if for no other, precarious—the prospect of such a degree of countenance and support from government, as may be capable of overcoming the obstacles inseparable from first experiments. (Report on Manufactures)

In the continuation of Wallace's account below, next note the government's decision to deliberately share the results of its research with private companies. This has been repeated throughout USA history, from metal-working machine tools designed and built in the federal armories after the War of 1812, to the Army officers ordered to assist, plan, superintend, and even manage railroad construction in the 1840s and 1850s, to the Navy's experiments during the Civil War on steam engine thermodynamics, to the famous Moore School lectures of summer 1946, when the Army's Ballistics Research Laboratory and the Navy's Office of Naval Research deliberately disseminated the knowledge needed to design and build electronic computers. This knowledge had been gained, at the government's expense, in the ENIAC, EDVAC, and other military projects which created the first working computers during World War Two. By deliberately spreading this knowledge, the government was acting in accord with Hamilton's plan, creating not only an entire new industry but a technological phase change of the entire economy.

While Convair was struggling with its F-102 design, the Grumman Aircraft Engineering Corporation was also working to develop its first supersonic carrier-based fighter, the F9F/F-11F Tiger. Although the area rule research was classified, the NACA released a confidential Research Memorandum on the subject to appropriately cleared aircraft manufacturers in September 1952. Just two weeks after receiving that memorandum, Grumman sent a group of its engineers to Langley to learn more about it. The information they brought back to Bethpage, New York, was immediately incorporated into the design, and in February 1953, Whitcomb was flown in to review the final design plans before construction on the prototype was begun. On April 27, 1953, the Navy signed a letter of intent with Grumman for the fighter, based on the Whitcomb-approved design. On August 16, 1954, the Grumman F9F-9 Tiger "breezed" through the sound barrier in level flight without the use of the afterburner on its Wright J-65 turbojet engine.

In the 1960s, Whitcomb and his colleagues in NASA began examining the problem of wing design at transonic and supersonic speeds. At these speeds, the air moving over the wing achieves Mach 1 velocity before the wing itself does. (This is what wings are supposed to do: force the air over a wing to move over a greater distance because of the wing chord, thus decreasing the air pressure over the top of the wing and creating lift.) But if a shock wave forms on top of the wing, drag on top of the wing can overpower much of the lift produced. In these circumstances, pilots almost always found that the aircraft became uncontrollable. Something else besides Whitcomb's area rule had to be found to solve this next problem.

The solution was first suggested in Germany in 1940, during World War Two, by K.A. Kawalki at the German Research Institute for Aviation Berlin-Adlershof. Kawalki and other German aerodynamacists were even able to test some wing designs in 1944, but by then Germany was already suffering severe damage from Allied bombing and was clearly going to lose the war. So it fell to Whitcomb to design, test, and perfect a supercritical airfoil in NASA's wind tunnels in the 1960s.

There was the obvious military application, but the real impetus came from passenger airlines, who had concluded that supersonic service was the obvious next step in the development of commercial aviation. The airlines were furiously lobbying aircraft manufacturers to come up with a supersonic airliner. When the British and French announced, in 1962, their intent to design and build what would become the Concorde, Pan Am quickly placed orders. In response, President John F Kennedy announced the creation of a National Supersonic Transport Program during his Graduation Day speech at the U.S. Air Force Academy on June 5th, 1963, and within a few weeks, the Federal Aviation Administration issued a request for SST proposals from the aviation industry.

The solution was first suggested in Germany in 1940, during World War Two, by K.A. Kawalki at the German Research Institute for Aviation Berlin-Adlershof. Kawalki and other German aerodynamacists were even able to test some wing designs in 1944, but by then Germany was already suffering severe damage from Allied bombing and was clearly going to lose the war. So it fell to Whitcomb to design, test, and perfect a supercritical airfoil in NASA's wind tunnels in the 1960s.

There was the obvious military application, but the real impetus came from passenger airlines, who had concluded that supersonic service was the obvious next step in the development of commercial aviation. The airlines were furiously lobbying aircraft manufacturers to come up with a supersonic airliner. When the British and French announced, in 1962, their intent to design and build what would become the Concorde, Pan Am quickly placed orders. In response, President John F Kennedy announced the creation of a National Supersonic Transport Program during his Graduation Day speech at the U.S. Air Force Academy on June 5th, 1963, and within a few weeks, the Federal Aviation Administration issued a request for SST proposals from the aviation industry.

Whitcomb found that the ideal wing design for supersonic flight required flattening the top soon after the leading edge, while incorporating a curve on the bottom of the wing at its trailing edge. This design moved the point on top of the wing where the air reaches supersonic speeds much farther back, minimizing the shock wave and creating less wave drag on the wing.

NASA drawing comparing a standard airfoil with a supercritical airfoil.

The Arab Oil Embargo of 1973 greatly weakened the desire of airlines to operate supersonic aircraft, and the Congress soon stopped funding for research and development of a supersonic transport. However, the supercritical airfoils developed by NASA under Whitcomb's direction, were found to provide superior lift and fuel efficiency, and have been widely incorporated in transonic airliner designs as well as military aircraft. It has been estimated that supercritical airfoils have given airlines a 15 percent jump in fuel efficiency each year for the past three decades.

Here is a great irony: the area rule and supercritical wings were developed at government expense, and have been crucial to the success of the business jets which the rich have come to prefer over commercial flights. The Cessna Citation X, for example, which was the world's fastest business jet since its introduction into service in July 1996, used supercritical wings to achieve its cruise speed of .90 Mach. In fact, Cessna consulted with Whitcomb on the aerodynamic design of the Citation X.

The irony, of course, is that many of the rich people who are jetting around the world using aerodynamic design principles developed and introduced by the government, are conservative and libertarian ideologues who insist that government can't do anything right!

In the 1980s, Whitcomb studied ways of making wing design even better. According to one report:

On July 6, 2018, at the Tuckahoe Steam and Gas Show eight miles north of Easton, Maryland, I had the pleasure of meeting William (Bill) H. Clarke, who is a NASA retiree. When I asked him what he had done at NASA, Mr. Clarke told me he had been a wind tunnel drive technician at the Langley Flight Research Center.

Obviously, I had to ask him: did you know Richard Whitcomb? Fortunately, Mr. Clarke had already seated himself in his walker. He was delighted to sit with me for the next ninety minutes and reminisce about his work, which justifiably gave him great pride.

Mr. Clarke worked personally with Dr. Whitcomb for his entire NASA career. His job was to monitor and maintain the massive electric motors and associated electrical equipment which drove the air in the wind tunnels. When the original facility was built at Langley in 1936, it was equipped with a synchronous electric motor that delivered 30,000 horsepower. By the 1970s, there were several other wind tunnels at Langley. The wind tunnel Mr. Clarke worked on used two 35,000 horsepower motors for two 10-foot diameter pipes, and a third 30,000 horsepower motor that took air out of the side of the tunnel. He said he lived three miles away from the facility, and when this tunnel was running, you could hear its whistling sound in his house.

William H. Clarke, at the Tuckahoe Steam and Gas Show, July 6, 2018.

In 1982, NASA rebuilt part of the Langley facilities as the National Transonic Facility, originally with motors of 100,000 horsepower. These were upgraded in a few years to 135,000 horsepower.

These motors used an awesome amount of electricity. The unitary wind tunnel, which Mr. Clarke never worked at, consumed 2.5 million kilowatt hours each month, he said. The 16-foot wind tunnel needed 84 megawatts to run its two fans and one compressor.

The wind tunnels Mr. Clarke worked on at the National Transonic Facilty (NTF) used nitrogen to decrease airstream temperatures as low as minus 275 degrees. He explained that there were three ways to get a wind tunnel to “chase high Reynolds numbers”: increase the air pressure; increase the speed, or decrease the temperature. (The Reynolds number is a measure of the ratio of inertial forces to viscous forces in an airflow. It basically describes whether the flow conditions are laminar (smooth) or turbulent. High Reynolds numbers are the goal for the design of high-speed and high-performance aircraft.)

Mr. Clarke said that when it was discovered the NTF used all 200 kiloliters of nitrogen in just 20 minutes, it was equipped with new 800 kiloliter tanks.

One of Mr. Clarke’s first remarks was that Dr. Whitcomb was a genius. According to Mr. Clarke, Whitcomb drove a Volvo P1800 sports car. “It was a bit dinged up,” Mr. Clarke recalled. “Dr. Whitcomb would often get deep into thought while driving, and sometimes ran into things.”

Though he was revered at Langley by the 1970s, Dr. Whitcomb was difficult to work with. “He burned out a tunnel technician every three months,” Mr. Clarke recalled. When he became deeply engaged in a problem, Whitcomb paid no attention to normal working hours. Mr. Clarke remembered one day when Dr. Whitcomb was at the tunnel when the morning shift started, and was still there when the afternoon and evening shifts came on duty. At some point during the night shift, Dr. Whitcomb, clearly near exhaustion, finally stood up, and walked out, without saying a word to anyone.

This description of the Unitary Wind Tunnel at Langley, from a 1957 NACA manual, gives some idea of the complexity of this facility. And this was in 1957!

When Whitcomb died at age 88 in October 2009, NASA posted an obituary on the the internet.

Richard Whitcomb looks over a model that incorporates his supercritical wing concept.

Richard Whitcomb looks over a model that incorporates his supercritical wing concept.

Image Credit: (NASA Photo)

This is an interesting video produced at Langley Research Center which shows the terrifying results of flutter on aircraft structures. Next time some conservative or libertarian begins venting against government, try to picture him or her taking a ride home in a non-NASA approved fluttering aircraft.

Some of the past posts in the series HAWB - How America Was Built

HAWB - Introduction - How America Was Built

Monday Jan 26, 2015

HAWB 1783 - Benjamin Franklin on the Augmentation of Wages - How America Was Built

Monday Feb 02, 2015

HAWB 1801 - Alexander Hamilton and Albert Gallatin - How America Was Built

Friday May 29, 2015

HAWB 1791 - Alexander Hamilton rejected Adam Smith

Tuesday Oct 20, 2015

The Power to Govern

Tuesday Dec 08, 2015

HAWB 1863 - Admiral Benjamin Franklin Isherwood and Steam Power - How America Was Built

Monday Dec 28, 2015

HAWB 1791-2001Hamilton and the Apple I-phone - How America Was Built

Sunday Feb 28, 2016

HAWB 1800s - It was NOT free trade - How America Was Built

March 11, 2016

HAWB 1800s - The Doctrine of High Wages - How America Was Built

April 1, 2016

HAWB 1870s - American producer class hero Peter Cooper - How America Was Built

May 22, 2016

A Short Crash Course in American Political Economy

November 25, 2016

HAWB – Creating America’s Amber Waves of Grain – How America Was Built

January 1, 2017

HAWB 1940s-1950s Timeline of computer development shows crucial role of government

December 3, 2017

How America Was Built: Alexander Hamilton versus Shareholder Value - HAWB December 1790

May 17, 2018

The Arab Oil Embargo of 1973 greatly weakened the desire of airlines to operate supersonic aircraft, and the Congress soon stopped funding for research and development of a supersonic transport. However, the supercritical airfoils developed by NASA under Whitcomb's direction, were found to provide superior lift and fuel efficiency, and have been widely incorporated in transonic airliner designs as well as military aircraft. It has been estimated that supercritical airfoils have given airlines a 15 percent jump in fuel efficiency each year for the past three decades.

Here is a great irony: the area rule and supercritical wings were developed at government expense, and have been crucial to the success of the business jets which the rich have come to prefer over commercial flights. The Cessna Citation X, for example, which was the world's fastest business jet since its introduction into service in July 1996, used supercritical wings to achieve its cruise speed of .90 Mach. In fact, Cessna consulted with Whitcomb on the aerodynamic design of the Citation X.

The irony, of course, is that many of the rich people who are jetting around the world using aerodynamic design principles developed and introduced by the government, are conservative and libertarian ideologues who insist that government can't do anything right!

In the 1980s, Whitcomb studied ways of making wing design even better. According to one report:

NASA' s Richard T. Whitcomb invented these nearly vertical wingtip extensions in the early 1970s as a means by which wing lift-to drag performance could be increased. Indeed, Whitcomb's research in 1976 indicated that winglets could reduce induced drag by 20 percent, resulting in about nine percent better lift-to-drag performance at 0.78 Mach for a specific wing loading. Whitcomb concluded that winglets produced twice the benefit of a wingtip extension with the equivalent area. As a result, winglets imposed much less weight and drag penalty than increasing wingspan. Far from the simple wing end plates patented by Lanchester in 1897, Whitcomb's early 1970s-vintage winglets were carefully designed airfoils that harnessed the energy of the wingtip vortex. Many of the original design principles still are used in the latest generation of winglets.

On July 6, 2018, at the Tuckahoe Steam and Gas Show eight miles north of Easton, Maryland, I had the pleasure of meeting William (Bill) H. Clarke, who is a NASA retiree. When I asked him what he had done at NASA, Mr. Clarke told me he had been a wind tunnel drive technician at the Langley Flight Research Center.

Obviously, I had to ask him: did you know Richard Whitcomb? Fortunately, Mr. Clarke had already seated himself in his walker. He was delighted to sit with me for the next ninety minutes and reminisce about his work, which justifiably gave him great pride.

Mr. Clarke worked personally with Dr. Whitcomb for his entire NASA career. His job was to monitor and maintain the massive electric motors and associated electrical equipment which drove the air in the wind tunnels. When the original facility was built at Langley in 1936, it was equipped with a synchronous electric motor that delivered 30,000 horsepower. By the 1970s, there were several other wind tunnels at Langley. The wind tunnel Mr. Clarke worked on used two 35,000 horsepower motors for two 10-foot diameter pipes, and a third 30,000 horsepower motor that took air out of the side of the tunnel. He said he lived three miles away from the facility, and when this tunnel was running, you could hear its whistling sound in his house.

William H. Clarke, at the Tuckahoe Steam and Gas Show, July 6, 2018.

In 1982, NASA rebuilt part of the Langley facilities as the National Transonic Facility, originally with motors of 100,000 horsepower. These were upgraded in a few years to 135,000 horsepower.

These motors used an awesome amount of electricity. The unitary wind tunnel, which Mr. Clarke never worked at, consumed 2.5 million kilowatt hours each month, he said. The 16-foot wind tunnel needed 84 megawatts to run its two fans and one compressor.

The wind tunnels Mr. Clarke worked on at the National Transonic Facilty (NTF) used nitrogen to decrease airstream temperatures as low as minus 275 degrees. He explained that there were three ways to get a wind tunnel to “chase high Reynolds numbers”: increase the air pressure; increase the speed, or decrease the temperature. (The Reynolds number is a measure of the ratio of inertial forces to viscous forces in an airflow. It basically describes whether the flow conditions are laminar (smooth) or turbulent. High Reynolds numbers are the goal for the design of high-speed and high-performance aircraft.)

Mr. Clarke said that when it was discovered the NTF used all 200 kiloliters of nitrogen in just 20 minutes, it was equipped with new 800 kiloliter tanks.

One of Mr. Clarke’s first remarks was that Dr. Whitcomb was a genius. According to Mr. Clarke, Whitcomb drove a Volvo P1800 sports car. “It was a bit dinged up,” Mr. Clarke recalled. “Dr. Whitcomb would often get deep into thought while driving, and sometimes ran into things.”

Though he was revered at Langley by the 1970s, Dr. Whitcomb was difficult to work with. “He burned out a tunnel technician every three months,” Mr. Clarke recalled. When he became deeply engaged in a problem, Whitcomb paid no attention to normal working hours. Mr. Clarke remembered one day when Dr. Whitcomb was at the tunnel when the morning shift started, and was still there when the afternoon and evening shifts came on duty. At some point during the night shift, Dr. Whitcomb, clearly near exhaustion, finally stood up, and walked out, without saying a word to anyone.

The drive system consists of a 20,000-horsepower liquid-rheostat-controlled woundrotor

starting motor driving through a gear box to the main drive line-up. This line-up

consists of a 63,333-horsepower synchronous motor driving six large capacity centrifugal compressors. The combined maximum overload capacity of the two motors is 100,000 horsepower for thirty minutes. The compressors can be arranged in five different configurations by valves in the interconnecting ducting in order to provide the wide range of volume flows and compression ratios required for the two test sections. Since the capacity of the drive system will supply only one of the test sections at a time, they cannot be operated simultaneously. The system that supplies air to the tunnel consists of compressors, vacuum pumps, and air dryer and air storage vessels as shown in Figure 1. It supplies air to the tunnel at a dewpoint of lower than -650 and at the required stagnation pressure, and provides for evacuation and recharging of the tunnel or portions thereof for purging and starting.

When Whitcomb died at age 88 in October 2009, NASA posted an obituary on the the internet.

"Dick Whitcomb's intellectual fingerprints are on virtually every commercial aircraft flying today," said Tom Crouch, noted aviation historian at the Smithsonian Institution. "It's fair to say he was the most important aerodynamic contributor in the second half of the century of flight."

Whitcomb came up with three important aeronautical innovations while working at NASA Langley, one in each decade of his career. If the area rule was Whitcomb's major accomplishment of the 1950s, his supercritical wing revolutionized the design of jet liners after the 1960s. The key was the development of an airfoil that was flatter on the top and rounder on the bottom with a downward curve on the trailing edge. That shape delayed the onset of drag, increasing the fuel efficiency of aircraft flying close to the speed of sound.

In the 1970s it was an article on birds that led Whitcomb to develop his third significant innovation -- winglets -- refining an idea that had been around for decades. Other engineers had suspected that end plates added to the wing tips could reduce drag. But the Langley engineer proved a simple vertical plate wasn't enough. "It is a little wing. That's why I called them winglets," said Whitcomb. "It's designed with all the care that a wing was designed." Winglets reduce yet another type of drag and further improve aerodynamic efficiency. Many airliners and private jets sport wingtips that are angled up for better fuel performance.

Richard Whitcomb looks over a model that incorporates his supercritical wing concept.

Richard Whitcomb looks over a model that incorporates his supercritical wing concept.Image Credit: (NASA Photo)

This is an interesting video produced at Langley Research Center which shows the terrifying results of flutter on aircraft structures. Next time some conservative or libertarian begins venting against government, try to picture him or her taking a ride home in a non-NASA approved fluttering aircraft.

Some of the past posts in the series HAWB - How America Was Built

HAWB - Introduction - How America Was Built

Monday Jan 26, 2015

HAWB 1783 - Benjamin Franklin on the Augmentation of Wages - How America Was Built

Monday Feb 02, 2015

HAWB 1801 - Alexander Hamilton and Albert Gallatin - How America Was Built

Friday May 29, 2015

HAWB 1791 - Alexander Hamilton rejected Adam Smith

Tuesday Oct 20, 2015

The Power to Govern

Tuesday Dec 08, 2015

HAWB 1863 - Admiral Benjamin Franklin Isherwood and Steam Power - How America Was Built

Monday Dec 28, 2015

HAWB 1791-2001Hamilton and the Apple I-phone - How America Was Built

Sunday Feb 28, 2016

HAWB 1800s - It was NOT free trade - How America Was Built

March 11, 2016

HAWB 1800s - The Doctrine of High Wages - How America Was Built

April 1, 2016

HAWB 1870s - American producer class hero Peter Cooper - How America Was Built

May 22, 2016

A Short Crash Course in American Political Economy

November 25, 2016

HAWB – Creating America’s Amber Waves of Grain – How America Was Built

January 1, 2017

HAWB 1940s-1950s Timeline of computer development shows crucial role of government

December 3, 2017

How America Was Built: Alexander Hamilton versus Shareholder Value - HAWB December 1790

May 17, 2018

No comments:

Post a Comment